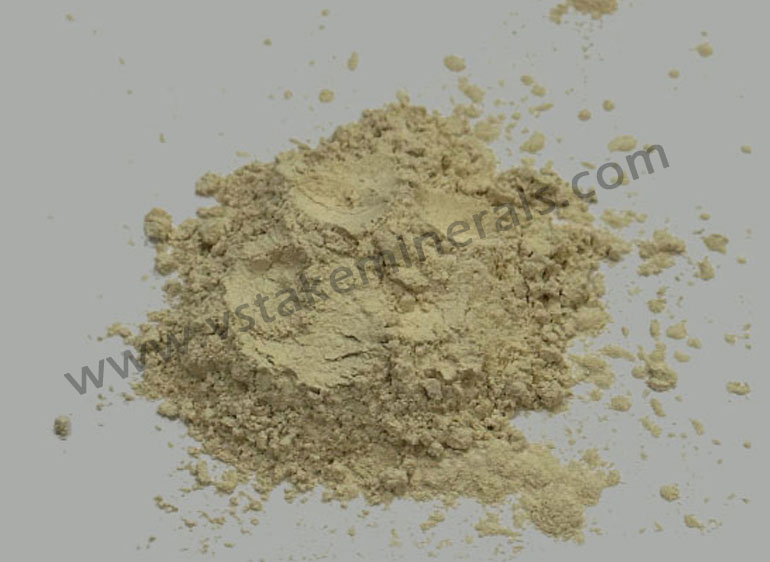

Colour and appearance: cream colour to off white colour

Uses:

1. Mullite powder is used in manufacturing refractories.

2. Mullite powder is used in manufacturing Kiln Furniture

3. Mullite powder er is used to manufacture foundry paints

4. Mullite powder is used in primary and secondary coating in investment casting

5. Mullite powder is used in manufacturing of high-alumina refractories

6. Mullite powder is also used in metal, glass, ceramic and cement industries

About Mullite:

We Vstake Solution Pvt. Ltd are Manufacturers, Suppliers, Provider, Wholesaler, Trader, Dealer, Exporters of Mullite Powder.

Mullite is a complex form of Al2O3 and SiO2. It is naturally available in form of ore in following minerals: Sillimanite, Andalusite, Kyanite. When these mullite ore minerals are heated ( Calcined) at certain temperature( 1600°C to 1800°C) there is change is the crystal structure of Al2O3 with crystal structure of SiO2 and thus mullitization takes place. Mullite can also be formed by calcining different types of high alumina clays with certain additives.Mullite powder is a fine-grained, powdered form of mullite, a mineral compound with the chemical formula Al6Si2O13. Mullite is known for its excellent high-temperature properties, low thermal expansion, and good thermal shock resistance. Mullite powder finds various applications across different industries. Here's some key information about mullite powder:

- Composition: Mullite is composed of aluminum oxide (Al2O3) and silicon dioxide (SiO2). It has a unique crystal structure with a 3:2 ratio of alumina to silica. Mullite powder is primarily composed of these compounds, with minor impurities depending on the source and manufacturing process.

- High-Temperature Properties: Mullite is known for its exceptional thermal stability and resistance to high temperatures. It can withstand temperatures well above 1,600 degrees Celsius (2,912 degrees Fahrenheit) without significant deformation or melting.

- Low Thermal Expansion Mullite exhibits low thermal expansion characteristics, making it suitable for applications where dimensional stability at high temperatures is critical.

- Manufacturing: Mullite powder is typically produced by heating raw materials, such as alumina and kaolin (a type of clay), at high temperatures in a controlled environment. The heating process promotes the formation of mullite crystals.

-

Applications:

- Refractories: Mullite powder is commonly used as a key raw material in the production of refractory materials, including refractory bricks, crucibles, and insulating materials. Mullite's high-temperature stability and low thermal expansion make it ideal for lining furnaces, kilns, and other high-temperature industrial equipment.

- Ceramics: Mullite powder is used in the ceramics industry to improve the properties of ceramic materials. It is often added to clay-based ceramics to enhance their thermal shock resistance and mechanical strength.

- Foundry: In the foundry industry, mullite-based materials are used in the construction of casting molds and crucibles, where they can withstand the high temperatures associated with metal casting.

- Electrical Insulation:Mullite ceramics are used as electrical insulators in high-temperature and high-voltage applications.

- Catalysis: BMullite-based catalysts are used in some chemical processes and catalytic reactions.

We Vstake Solution Pvt. Ltd are deeply engaged in offering a wide array of Mullite Powder to our valuable Clients located in Mumbai, in Navi Mumbai, in Thane and all over India.

Enquiry Now